High-Fidelity Simulation of Complex Suspension Flow for Practical Rheometry

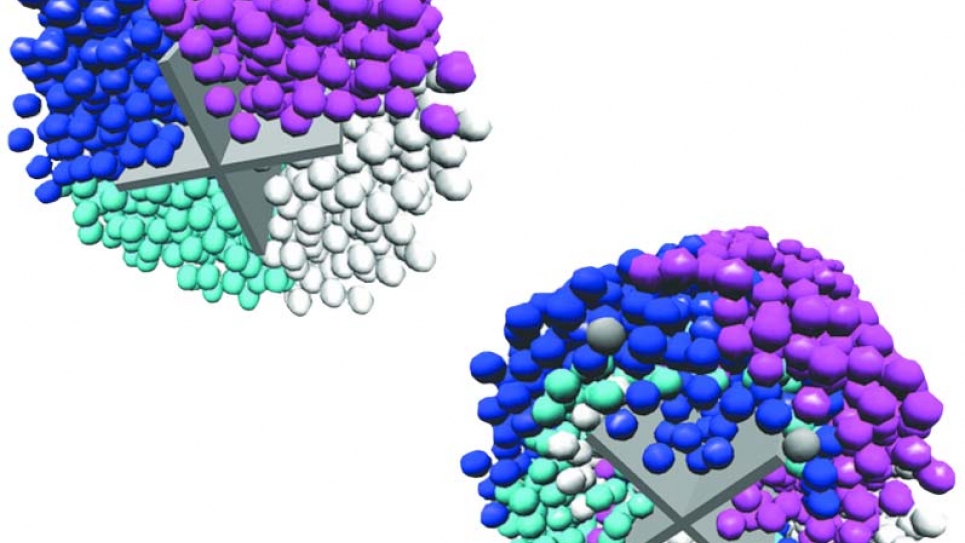

Flow properties of large-particle suspensions, such as concrete, cannot now be measured accurately in industrial settings. Flow simulations with many thousands of particles with a wide range of sizes and shapes in a non-Newtonian fluid matrix will enable the design of rheometers that will revolutionize the use of these instruments.

The project’s previous three-year INCITE award, granted in 2008, gave researchers the computing power to perfect their algorithms and to test parameters such as system size and the width of the size distribution of the suspended particles in a large-scale parallel approach. The researchers now seek to apply this capability to very large-scale parallel simulations needed to solve the problem of quantitatively extracting fundamental rheological parameters such as stress and strain rate from measured quantities such as torque and angular velocity in non-analytical rheometer and mixing geometries. Analysis and visualization of the simulated flow will enable the researchers to develop a fundamental framework to understand important physical mechanisms that control the flow of such complex fluid systems.

Results from this study will advance the science of dense suspensions and enable the measurement science needed for rheometer design for these systems. This will solve a critical outstanding problem in the cement and concrete industry, and will also have an enormous influence on the wide array of industries that use vane rheometers and mixers, from food processing to water treatment, to coatings, and to pharmaceuticals.