Computational Design of Novel Multiscale Concrete Rheometers

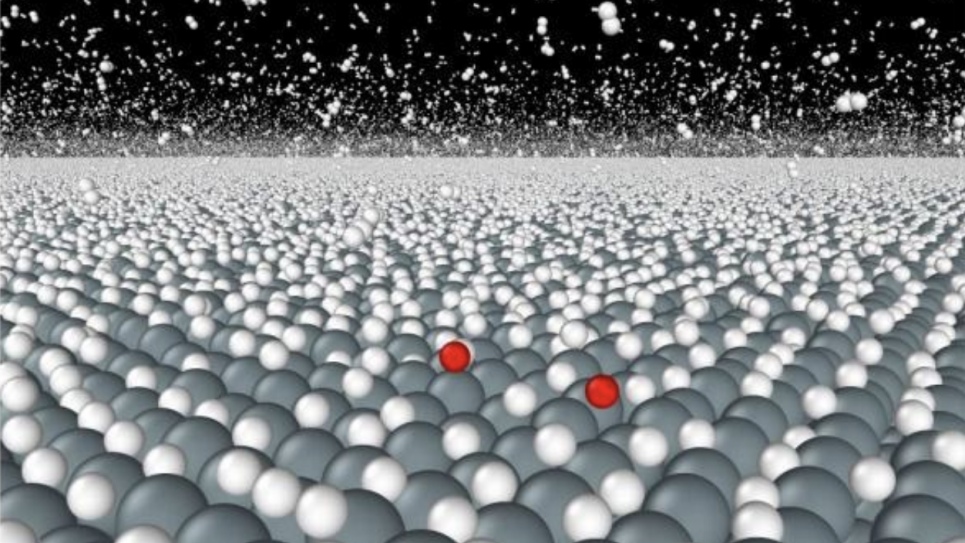

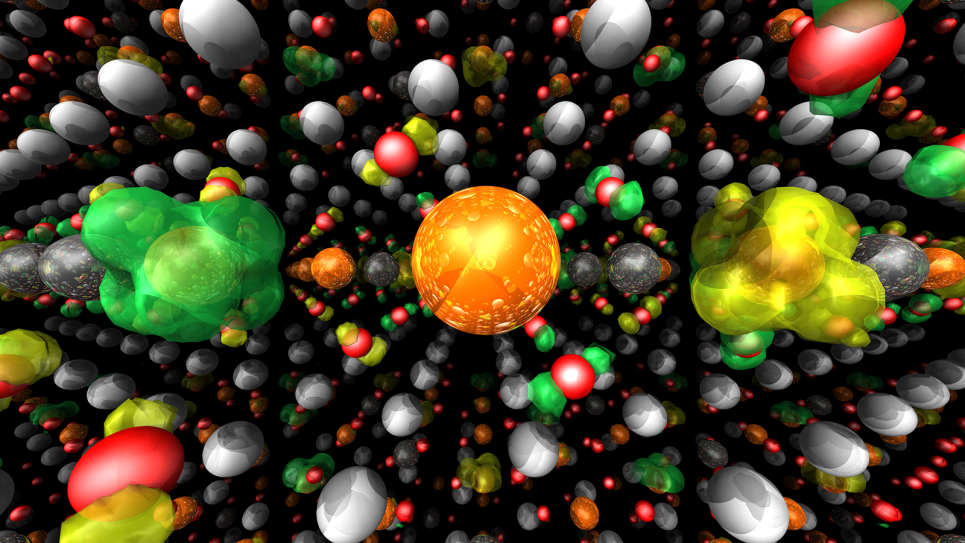

Understanding the mechanisms of dispersion or agglomeration of particulate matter in complex fluids, such as suspensions, is of technological importance in many industries. A basic goal of this project is to advance the understanding of the flow properties of fresh concrete, which is a dense suspension composed of cement, water, sand, and rocks.

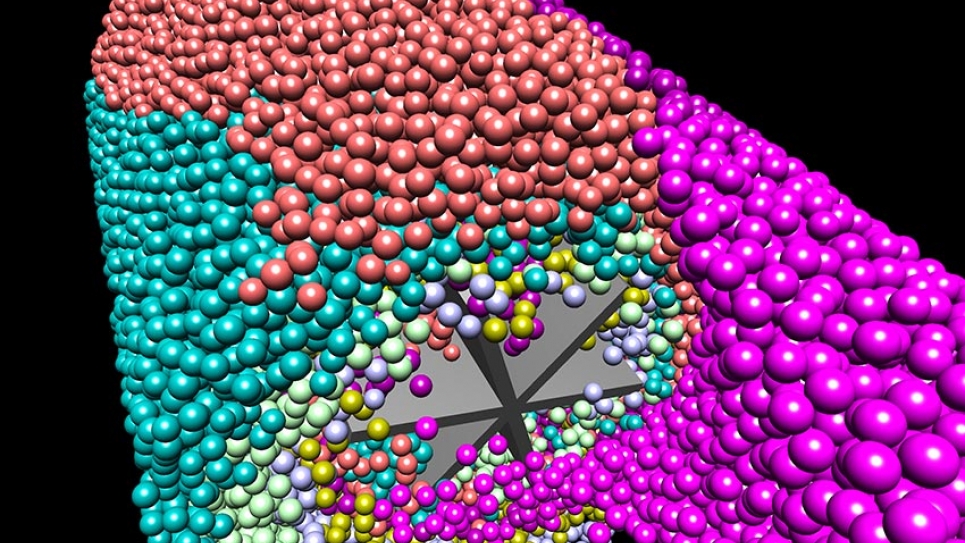

The National Institute of Standards and Technology (NIST) used a recent INCITE allocation to aid in the design and development of a Standard Reference Material (SRM), which is a mortar (a cement paste matrix fluid plus sand inclusions), used to calibrate rheometers in the field. Project researchers will now extend their modeling capability to more novel rheometer designs to resolve basic problems in rheological measurements of mortars and concrete, such as sedimentation, which results in an undesired heterogeneous mixture. Utilizing the results of earlier project phases as a foundation, this current phase will run massively parallel computations to help design the actual rheometer blades themselves. Optimizing blade shape and rotational speed helps avoid problems of sedimentation and other artifacts that can occur in currently available rheometers.

Presently, there is interest in screw-like or double-helix rheometer blade designs that allow for the mixing of suspensions such that a more representative, homogeneous mixture is maintained. This work will model flow in single- and double-helical rheometers. Also, the current project phase will finally unite the major length scales of concrete rheology—cement paste, mortar, and concrete—for traditional and novel rheometer designs. NIST has the capability to manufacture these new designs, and to perform experimental validation on the predicted rheological measurements produced by these novel blade designs. Results will prove useful in the many industries that make use of dense, complex suspensions.