Improving Aircraft Engine Combustor Simulations

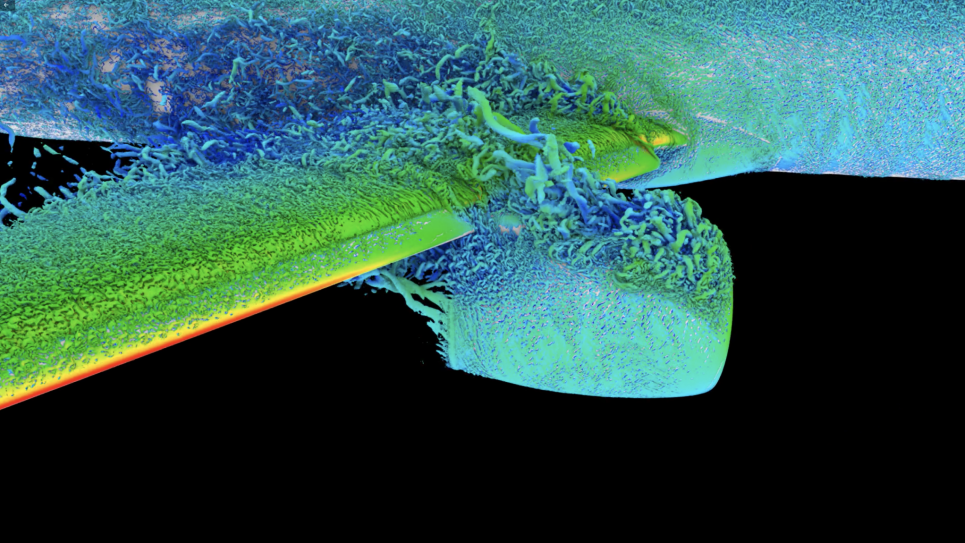

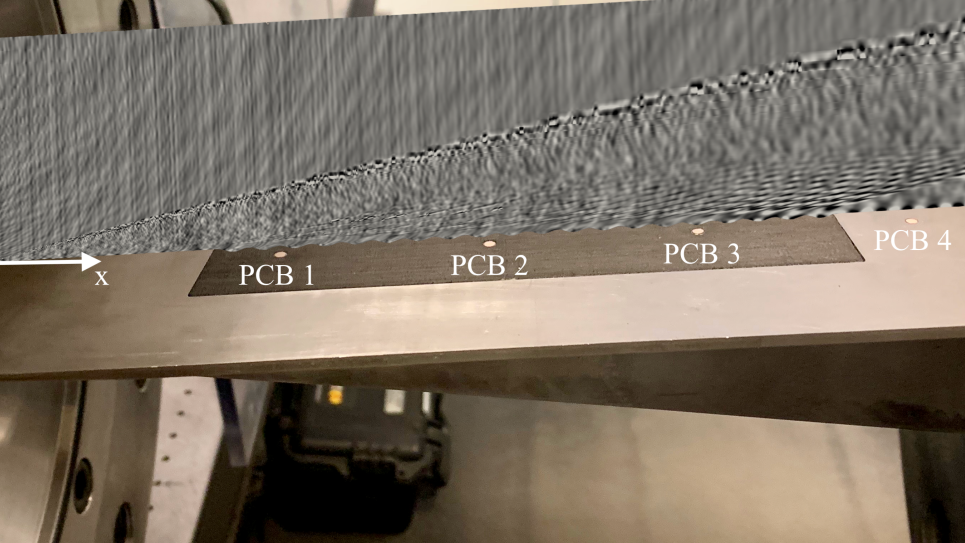

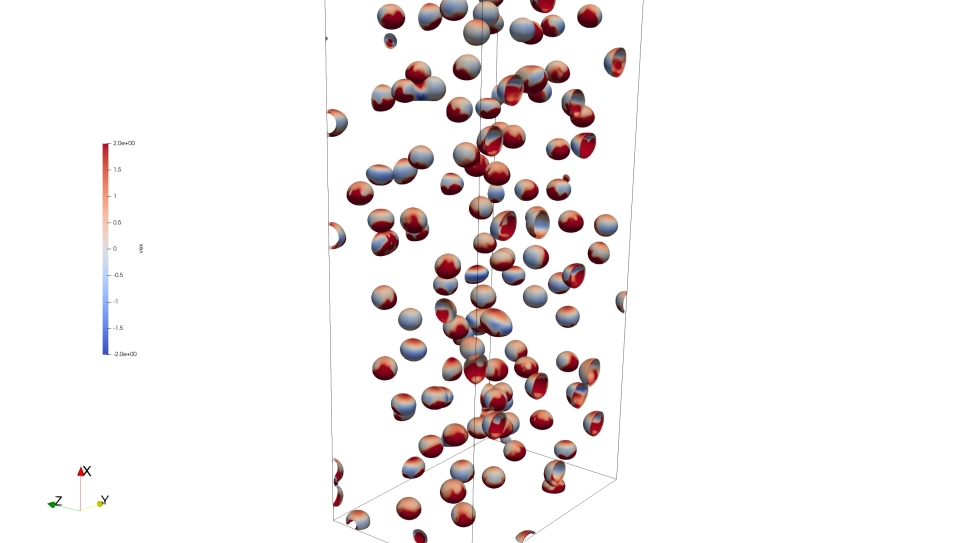

A jet engine combustor combines air flowing faster than a hurricane with swirling fuel to generate the extraordinary release of heat that ultimately powers the aircraft. Understanding these complex physical and chemical interactions is critical to fuel efficiency and emissions performance, but physical testing can be difficult and time consuming.

Approach

Computer simulation of the complex physics of a combustor creates a “virtual test,” thus reducing the need for physical testing. Pratt & Whitney has been exploring leading-edge combustor design methods using the Blue Gene/P supercomputer at the Argonne Leadership Computing Facility as part of DOE’s INCITE program.

Results/Accomplishments

This INCITE project has led to improved capabilities and reduced solution times for 3-D combustor simulations. The work has been a key enabler for the depth of understanding needed to meet emissions goals. INCITE 2006-2007 technologies are now being applied to Pratt & Whitney’s next-generation, low-emission Geared Turbofan™ engine. This groundbreaking engine will deliver unprecedented reductions in emissions, noise, and cost of ownership compared to current engines.

Future Efforts

Researchers plan to use the Blue Gene/P to complete high-fidelity simulations that will give new insights on aerodynamic behavior inside an operating jet engine combustor.