Reactive MD Simulations of Electrochemical Oxide Interfaces at Mesoscale

Electrochemical oxide interfaces lie at the center of a broad spectrum of physico-chemical systems relevant to energy security and environmental protection—ranging from electrochemical energy conversion/storage systems to corrosion surfaces.

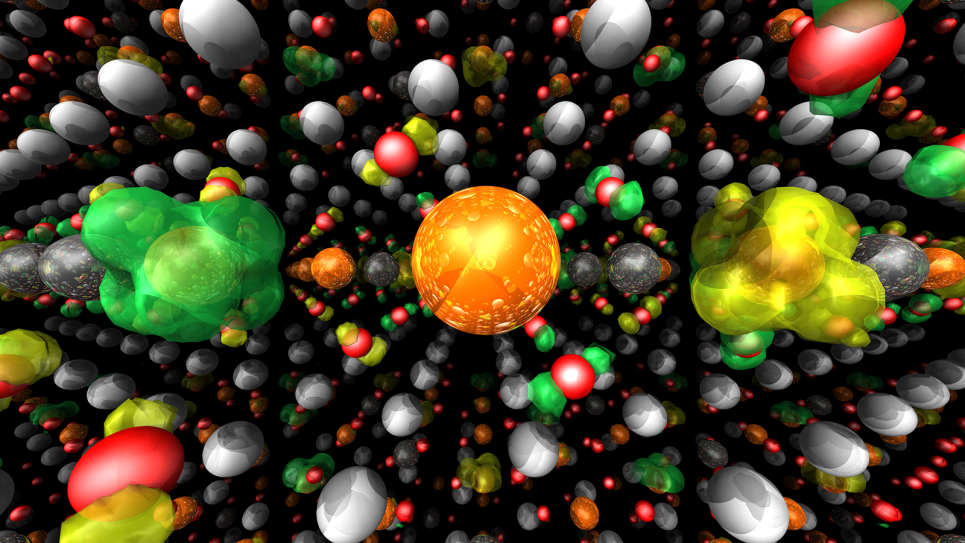

The dynamical processes in such oxide interfaces combine the remarkable complexity of numerous interfacial reactions, transport phenomena and interface structural evolution with the formidable subtleties of material defect chemistry. Breakthroughs in the fundamental understanding of mesoscale, or intermediate, electrochemical oxide interfaces are urgently needed for the design and development of novel functional oxide materials for energy applications.

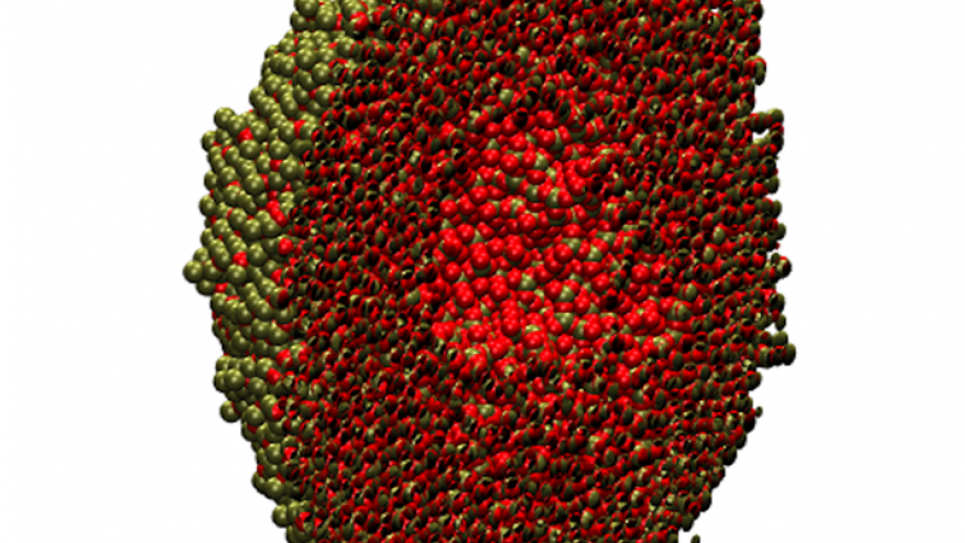

Given the structural and compositional complexity of oxide materials and their interfaces, it is not surprising that both the passive state and functional properties of oxides and oxide interfaces are related to the defects, which in turn are dramatically influenced by the synthesis conditions. One approach to tuning oxide defect imbalances at room temperature involves the use of an electric field to stimulate oxide growth beyond what is possible through thermal diffusion.

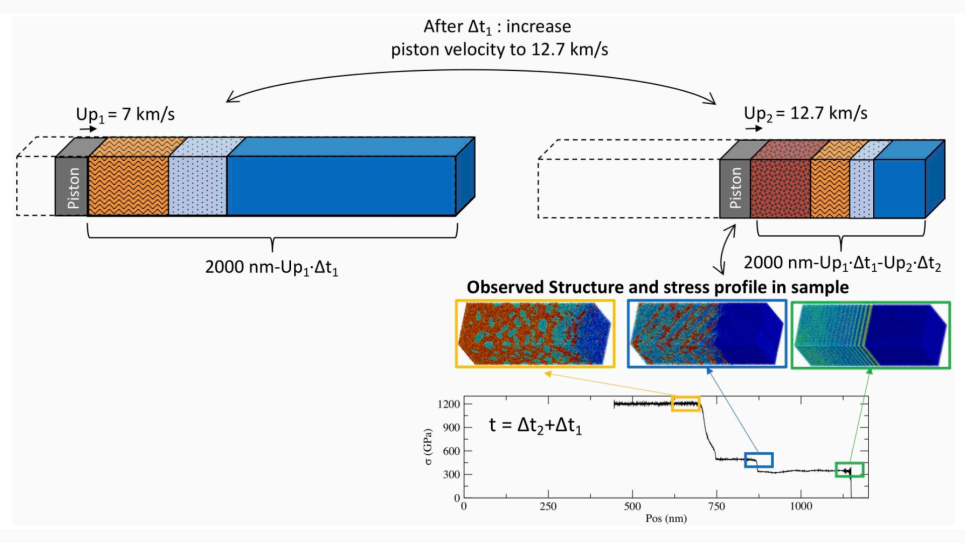

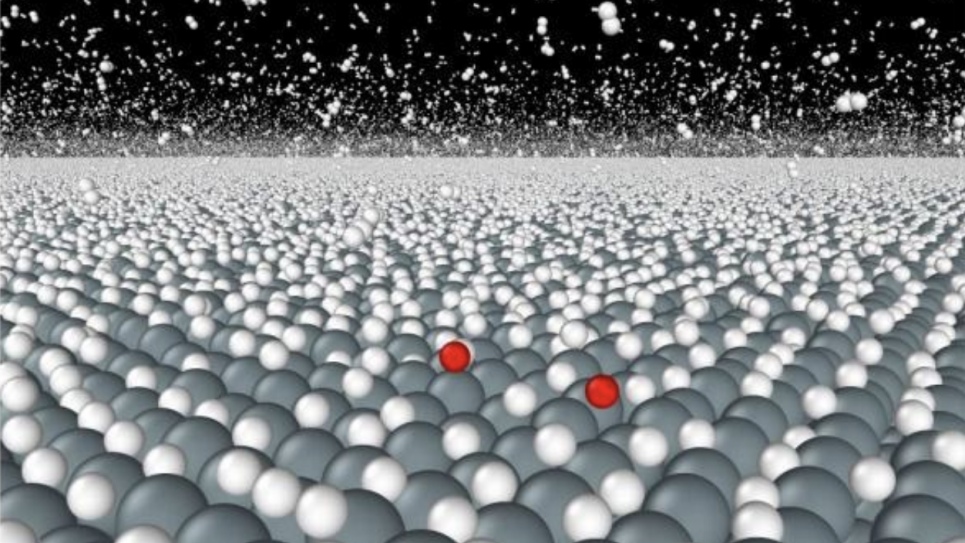

The proposed computational research utilizing atomistic simulations such as classical molecular dynamics (MD) with ReaxFF—reactive force field—will demonstrate the potential of electrical field application for ceramics processing. This integrated simulation-experimental protocol will determine the way electrical field application affects the transport processes during oxidation, oxide growth, and sintering, and will establish methods for their exploitation in practical processes and applications.

This INCITE project could result in the development of a universal platform that harvests the unique advantages of electrical field application during ceramics sintering, benefiting the field of ceramics processing and industries that rely heavily on ceramics technologies, including energy-relevant industries.