Carbon capture is a critical technology in reducing greenhouse gas emissions from power plants and other industrial facilities. But a suitable material for effective carbon capture at low cost has yet to be found. One candidate is metal-organic frameworks, or MOFs. This porous material can selectively absorb carbon dioxide.

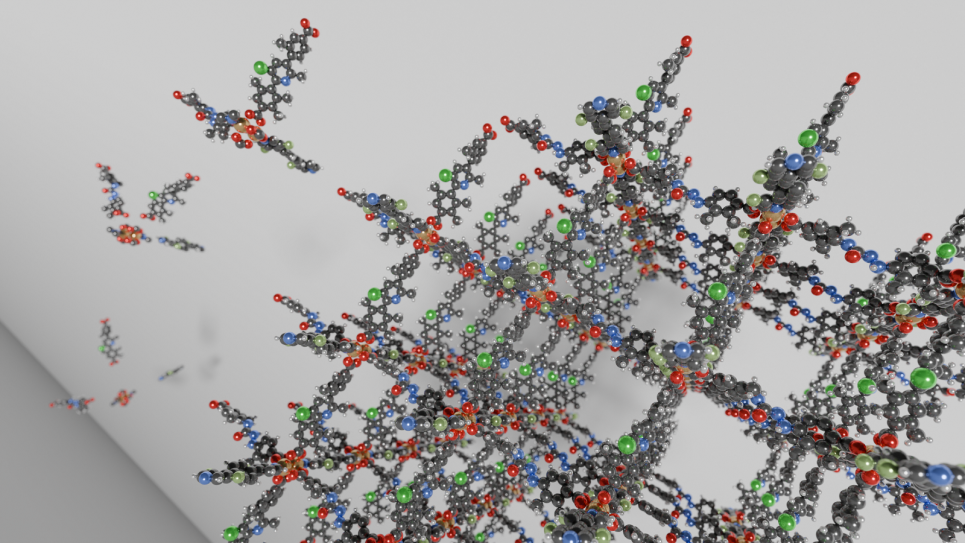

MOFs have three kinds of building blocks in their molecules — inorganic nodes, organic nodes and organic linkers. These can be arranged in different relative positions and configurations. As a result, there are countless potential MOF configurations for scientists to design and test.

To speed up the discovery process, researchers from the U.S. Department of Energy’s (DOE) Argonne National Laboratory are following several pathways. One is generative artificial intelligence (AI) to dream up previously unknown building block candidates. Another is a form of AI called machine learning. A third pathway is high-throughput screening of candidate materials. And the last is theory-based simulations using a method called molecular dynamics.

Joining Argonne in this project are researchers from the Beckman Institute for Advanced Science and Technology at the University of Illinois Urbana-Champaign (UIUC), the University of Illinois at Chicago and the University of Chicago.

Designing MOFs with optimal carbon selectivity and capacity is a significant challenge. Until now, MOF design has relied on painstaking experimental and computational work. This can be costly and time-consuming.

By exploring the MOF design space with generative AI, the team was able to quickly assemble, building block by building block, over 120,000 new MOF candidates within 30 minutes. They ran these calculations on the Polaris supercomputer at the Argonne Leadership Computing Facility (ALCF). The ALCF is a DOE Office of Science user facility.

They then turned to the Delta supercomputer at UIUC to carry out time-intensive molecular dynamics simulations, using only the most promising candidates. The goal is to screen them for stability, chemical properties and capacity for carbon capture. Delta is a joint effort of Illinois and its National Center for Supercomputing Applications.

The team’s approach could ultimately allow scientists to synthesize just the very best MOF contenders. “People have been thinking about MOFs for at least two decades,” said Argonne computational scientist Eliu Huerta, who helped lead the study. “The traditional methods have typically involved experimental synthesis and computational modeling with molecular dynamics simulations. But trying to survey the vast MOF landscape in this way is just impractical.”

Even more advanced computing will soon be available for the team to employ. With the power of the ALCF’s Aurora exascale supercomputer, scientists could survey billions of MOF candidates at once, including many that have never even been proposed before.

What’s more, the team is taking chemical inspiration from past work on molecular design to discover new ways in which the different building blocks of a MOF could fit together.

“We wanted to add new flavors to the MOFs that we were designing,” Huerta said. “We needed new ingredients for the AI recipe.” The team’s algorithm can make improvements to MOFs for carbon capture by learning chemistry from biophysics, physiology and physical chemistry experimental datasets that have not been considered for MOF design before.

To Huerta, looking beyond traditional approaches holds the promise of a transformative MOF material — one that could be good at carbon capture, cost-effective and easy to produce.

“We are now connecting generative AI, high-throughput screening, molecular dynamics and Monte Carlo simulations into a standalone workflow,” Huerta said. “This workflow incorporates online learning using past experimental and computational research to accelerate and improve the precision of AI to create new MOFs.”

The atom-by-atom approach to MOF design enabled by AI will allow scientists to have what Argonne senior scientist and Data Science and Learning division director Ian Foster called a “wider lens” on these kinds of porous structures. “Work is being done so that, for the new AI-assembled MOFs that are being predicted, we incorporate insights from autonomous labs to experimentally validate their ability to be synthesized and capacity to capture carbon,” Foster said. “With the model fine-tuned, our predictions are just going to get better and better.”

A paper based on the study was authored by Hyun Park, Xiaoli Yan, Ruijie Zhu, Eliu Huerta, Santanu Chaudhuri, Donny Copper, Ian Foster and Emad Tajkhorshid. It appeared in the online issue of Nature Communications Chemistry.

“The study demonstrates the great potential of using AI-based approaches in molecular sciences,” said UIUC’s Tajkhorshid. “We hope to extend the scope of the approach to problems such as biomolecular simulations and drug design.”

“This work is a testament to the collaboration between graduate students and early-career scientists from different institutions who came together to work on this important AI for science project,” Huerta said. “The future will stay bright as we continue to inspire and be inspired by talented young scientists.”

The work was supported by DOE’s Office of Science, Office of Advanced Scientific Computing Research, laboratory-directed research and development funds, and the National Science Foundation.