High-Fidelity Physics Simulations. Image: Emily Shemon, Argonne National Laboratory

This project will perform a series of high-fidelity multiphysics calculations to compute a set of hot channel factors for a lead-cooled fast reactor design using DOE-NEAMS codes.

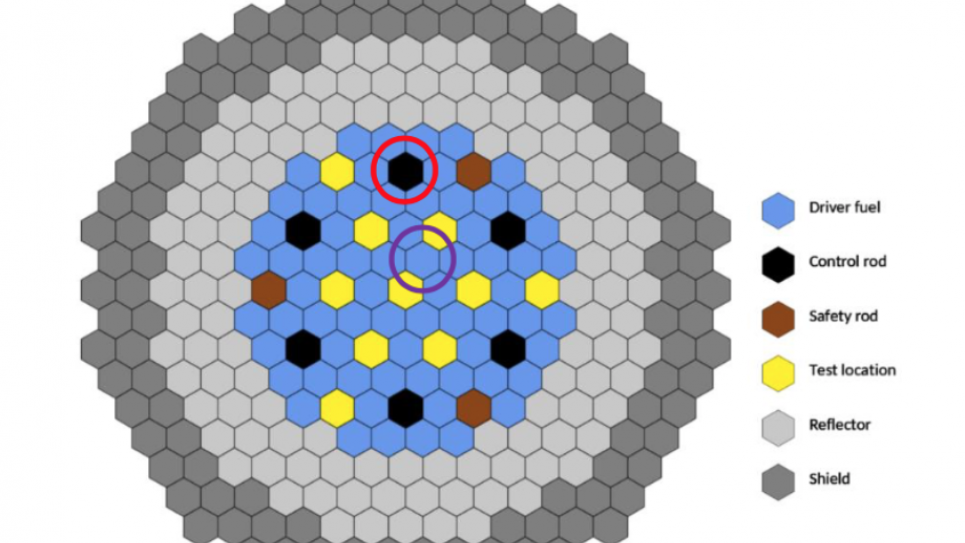

Under a multi-laboratory effort, DOE is designing the VTR, a proposed experimental nuclear reactor based on fast spectrum sodium-cooled technology. Upon operation, the facility will be used to assess the performance of irradiated materials such as accident-tolerant fuel for inclusion in U.S. advanced nuclear reactor technology. Design for the fuel assemblies is relatively mature; however, the control assembly design has not been finalized due to competing parameters which have not yet been optimized. Multiphysics simulation will be applied to analyze peak temperatures in both the control assembly and fuel assembly for a specific control assembly design. Designs for core components having a significant impact on the flow through the VTR assemblies have also not been finalized. The pressure drop induced by the required core components is a key design parameter for which uncertainty must be minimized. Accurately predicting pressure drop across complex component designs requires detailed simulations to properly resolve important flow features. High fidelity simulation will be applied to yield pressure drop data which will directly impact design decisions for these components and the overall plant design.

High fidelity multiphysics simulations will also be performed for the lead-cooled fast reactor (LFR) being developed by Westinghouse Electric Company, a world leader in the development and commercialization of nuclear power plants. Known as a leader in thermal, light water reactor technology, the company is expanding its portfolio with advanced designs including non-water coolant and fast spectrum systems due to the potential efficiency and safety of such systems.

Among other advantages, the Westinghouse LFR can be built at reduced cost, more efficiently utilize natural resources, and operate at higher thermal efficiencies than existing commercial light water reactors. Aligning national laboratory R&D with industry needs is a key priority, as indicated by a variety of funding opportunity announcements (DOE-NE’s GAIN Gateway for Accelerated Innovation in Nuclear program, ARPA-E’s MEITNER Modeling-Enhanced Innovations Trailblazing Nuclear Energy Reinvigoration program) and changes in DOE-NE programmatic direction. Therefore, a series of high fidelity multiphysics calculations will be performed to compute a set of hot channel factors (HCF) for this industry LFR design using DOE-NEAMS codes. HCFs are critical safety factors that account for how uncertainties in physical parameters, manufacturing tolerances, modeling approximations, or experiments impact the worst case scenario reactor temperatures. There are no historical HCF datasets available for LFRs, so the results of the proposed calculations will be very informative for the reactor technology industry; including Westinghouse, which has already identified priority hot channel factors to be assessed here.