This project aims to demonstrate, for the first time, the viability of assessing the long-term properties necessary for the design of new, high-temperature energy generation technologies. To do so, the researchers will carry out a large grid of molecular dynamics calculations spanning several orders of magnitude in strain rate and initial defect density.

Traditional structural engineering design considers only time-independent failure modes: either a structure will immediately fail under some combination of loads or it will not. In contrast, for high-temperature structural components failure is governed by time-dependent creep. Therefore, to design safe and effective structural components for next-generation high temperature nuclear reactors, concentrating solar power systems, supercritical fossil fuel plants, and petro-chemical processing facilities, engineers need to know how a material will behave under very long periods of load at high temperatures. This information is often not available because of the very long time required to complete the necessary experiments.

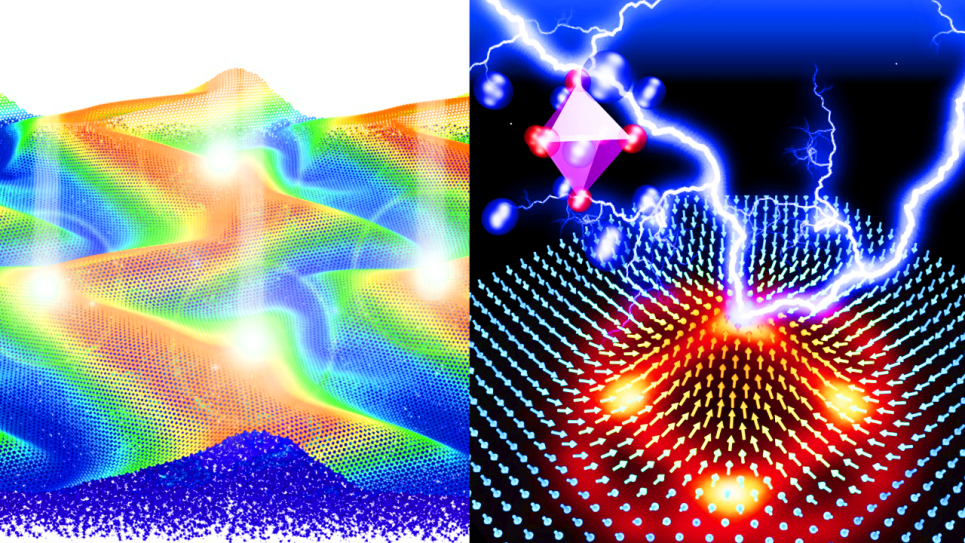

Ideally, the required time-dependent material properties could be generated from first-principles simulations upscaled to engineering properties using multiscale, physics-based models. This would reduce or avoid lengthy tests and decrease the time between the discovery of a new material and the point it actually enters service. However, there are two key challenges in advancing models of high temperature structural deformation and damage down to the atomistic length scale: (1) time scale -- MD simulations typically span microseconds at best, creep deformation occurs over a period of years; and (2) modeling sufficient defects -- creep deformation depends on defects in the metal's crystal lattice (dislocations, vacancies, and voids), not the bulk lattice properties. Relevant MD calculations would need to contain enough atoms to represent a statistically meaningful quantity of defects.

To address the first issue, the researchers will use a novel multiscale method based on homogenizing the rate of state variables, rather than the variables themselves, interpolating sparse MD data with machine learning techniques, and assuming steady state behavior to extrapolate in time. The team will address the second issue with large-scale use of HPC. Recent results published in Nature (Zepeda-Ruiz et al., 2017) demonstrate the MD calculations with size from 15M to 300M atoms are both feasible with current HPC resources and provide information that is directly relevant to crystal plasticity modeling.

This ALCC project will support a large grid of MD calculations spanning several orders of magnitude in strain rate and initial defect density. Specifically, the team will complete 70 calculations on 16M atom boxes. The researchers developed and tested the potential and the postprocessing methods required to generate data for the higher length scale models using a discretionary grant from Argonne National Laboratory. Additionally, the time requested in this proposal would cover the cost of running higher length scale calculations to extract useful engineering material properties, including temperature/time dependent material flow strengths and creep predictions.

This project will be completed in partnership with scientists from CNEA (Argentina’s Atomic Energy Agency). Successful completion would, for the first time, demonstrate the viability of assessing the long-term properties necessary for the design of new, high-temperature energy generation technologies.