ALCF Simulations Help Lay the Foundation for Better, Greener Concrete

Researchers from the National Institute of Standards and Technology (NIST) are conducting simulations at the Argonne Leadership Computing Facility (ALCF) to advance the measurement science of concrete and to gain a fundamental understanding of how it flows.

NIST, an agency of the U.S. Department of Commerce, was established by Congress at the turn of the century to develop a measurement infrastructure to help improve U.S. industrial competitiveness. Today, NIST measurements support every technological creation from nanoscale devices to global communication networks.

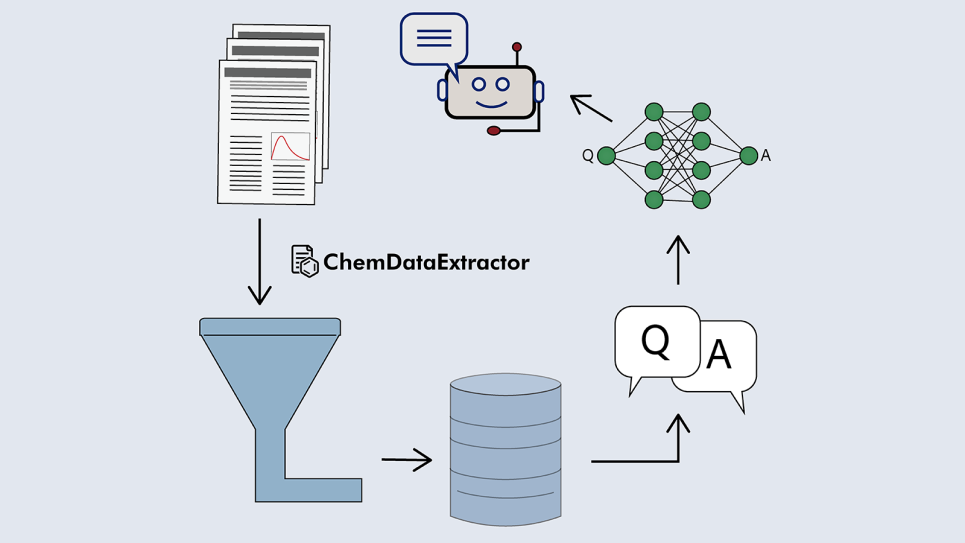

For their project at the ALCF, the NIST research team is combining data from large-scale simulations with theoretical work and physical experiments to create Standard Reference Materials (SRMs) for concrete to allow for more accurate viscosity measurements. SRMs are certified and issued by NIST for use in quality control, regulatory compliance, product development, and scientific research for a wide variety of materials, including steel, rubber, and plastics.

NIST has developed and released its first SRM to calibrate rheometers (blender-like devices used to measure flow properties) for cement paste. The properties of that material were subsequently used as an input to the simulation code being run at the ALCF, which is feeding into the development of SRMs for mortar (cement and sand) and concrete (mortar and gravel). The mortar SRM is expected to be available soon.

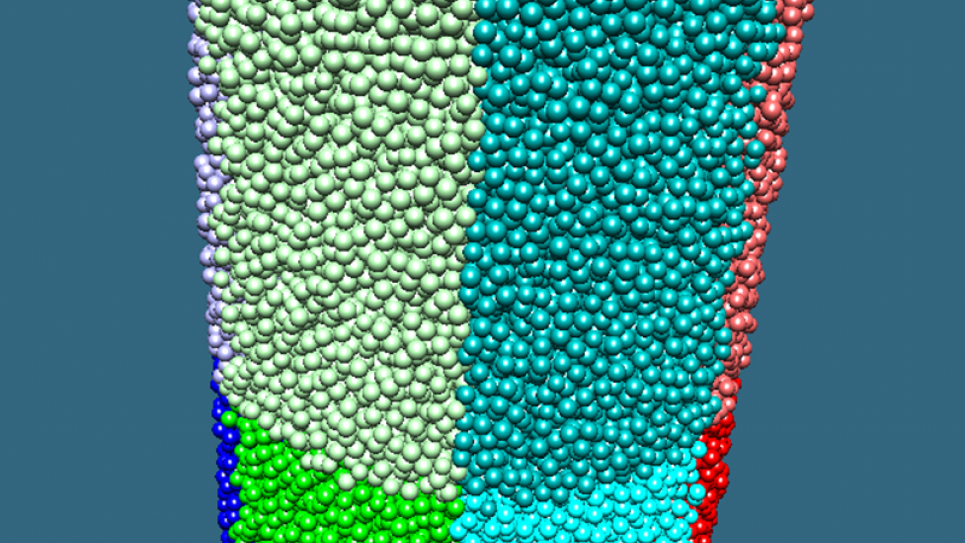

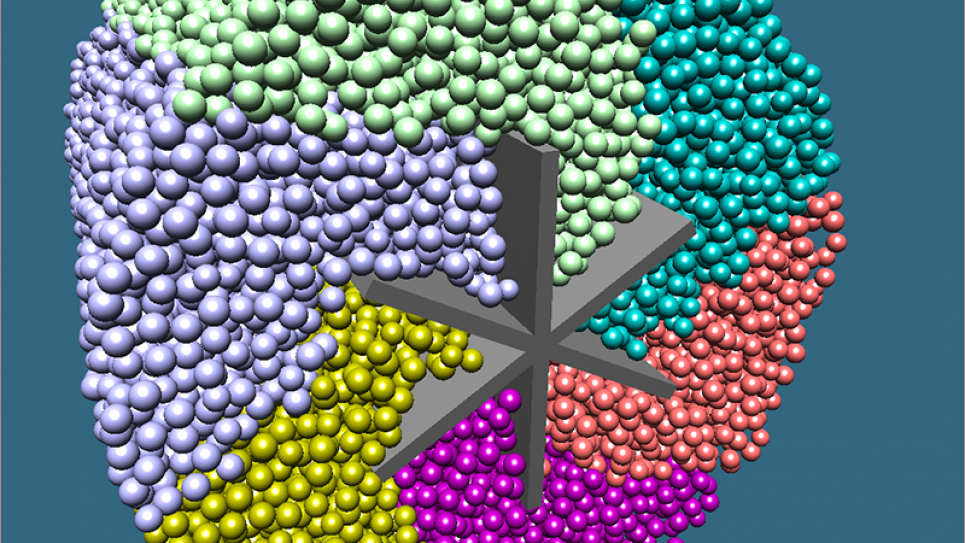

“The reference materials that will be produced for the aggregates in mortar, for example, won’t be actual sand—they’ll be small spheres identical in size, shape, weight, and hardness,” said William George, NIST computer scientist and project principal investigator. “The reference material will be as close to sand as we can get, but its known properties will allow us to reproduce viscosity results in the field.”

The SRMs will enable accurate predictions of the flow of concrete, which is essential to exploring the use of new, more environmentally friendly ingredients for concrete mixtures. Alternative materials are key to helping reduce the energy consumption and pollution caused by manufacturing cement, one of the main components of concrete.

Additionally, the SRMs will help to improve the workability of concrete by creating standardized measurements that would allow builders to request a specific concrete formulation with reliable, repeatable results.

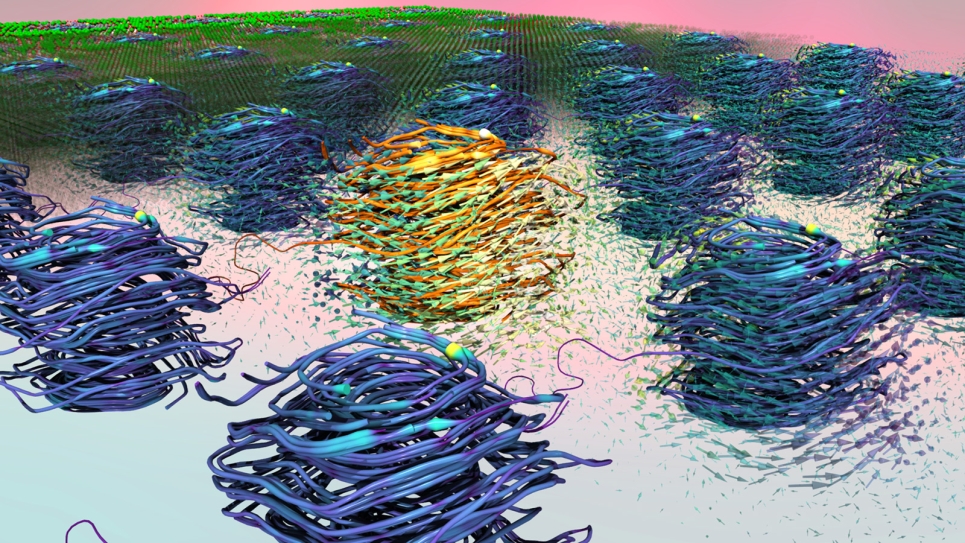

Due to the complex nature of concrete, which is a dense suspension comprised of water, cement, and an aggregate, such sand or gravel, the use of high-performance computers is required to develop methods that accurately measure its properties.

“You need massive amounts of memory for these simulations, and a machine that’s large enough to handle the load of computing the forces at work in the mix,” George said. “It’s a very computationally intensive problem, which is why we run it here at the ALCF where there are resources to match our needs.”

Building on their past ALCF work, which dates back to 2008, the NIST project was awarded another 20 million core-hours at the facility in 2013 through the U.S. Department of Energy’s Innovative and Novel Computational Impact on Theory and Experiment (INCITE) program.

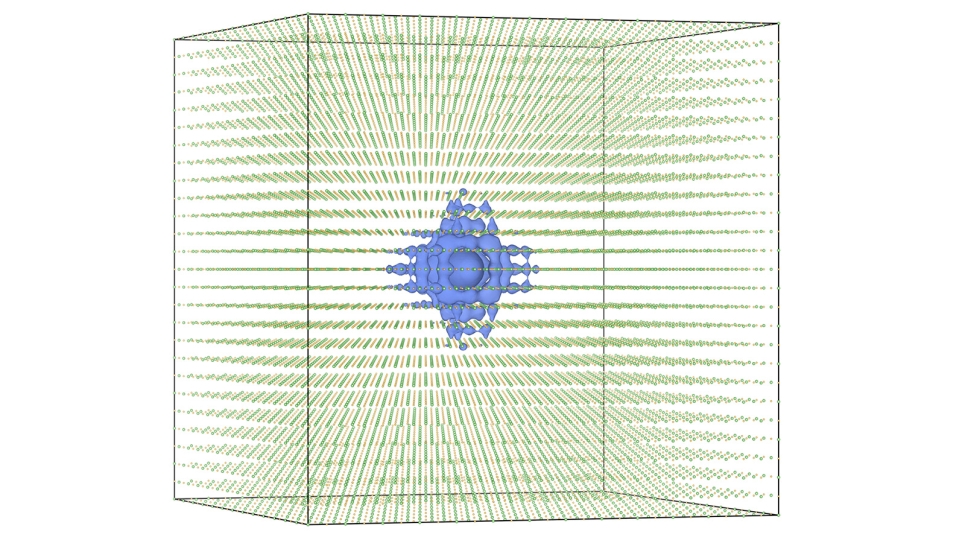

With the power of the ALCF’s supercomputers, the scientists are able to validate experimental findings and study dense suspensions in much more detail than can be done in a laboratory.

“In a lab experiment, you can’t see what’s going on inside the concrete,” said George. “You can’t see what causes the viscosity to change or what’s influencing it. But our computer simulations allow us to visualize the forces at work inside the suspension.”